This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

Lifecycle for elevators

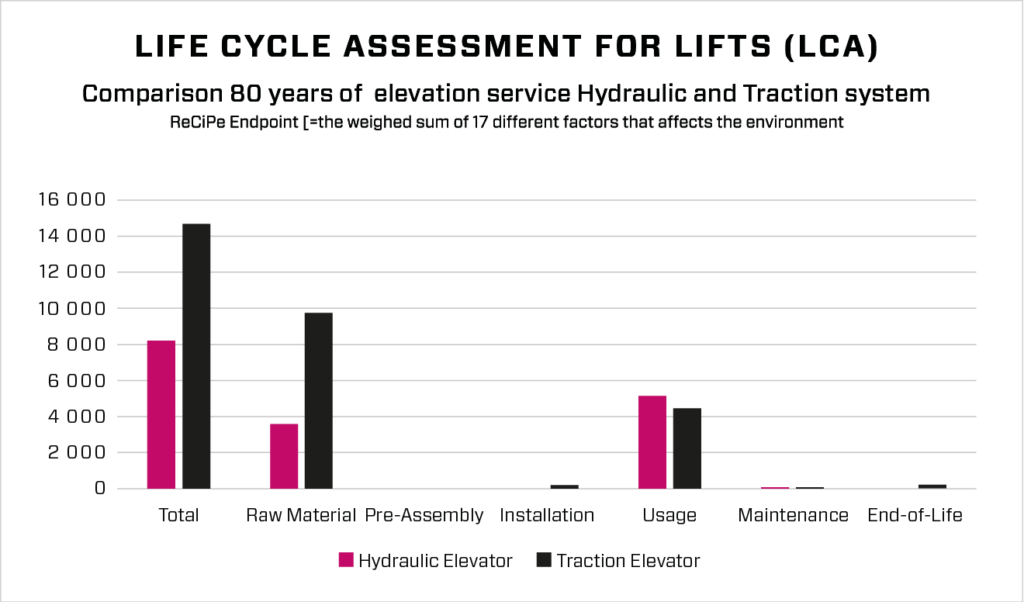

We have had a life cycle analysis done for a 4-storey elevator in a residential building. It clearly shows that the material used to manufacture the elevator has a significantly greater negative impact on the environment than that from the operation of the elevator during the life of the property.

In this example, both elevators are installed in a new residential building in Berlin. The hydraulic elevator is then modernized every 20 years and the elevator with counterweight is replaced completely at the same interval.

Environmental impact from the material

For most people in the elevator industry, the results are surprising. Until now, all focus has been on reducing energy consumption in operation and much has been improved here. But now it’s time to also look at the environmental impact of the material used.

Elevator without counterweight in lower buildings

Our life cycle analysis clearly shows that it is most appropriate to have an elevator without a counterweight for lower buildings, such as residential buildings.

37,000 kg less carbon dioxide emissions

We estimate the lifespan of a residential building at 80 years and the lifespan of the elevator at 20 years. The environmental impact of a counterweight elevator will then be 37,000 kg more carbon dioxide emissions compared to a hydraulic elevator. The amount of carbon dioxide emissions is equivalent to driving a petrol-powered car that meets the EURO 5 emission requirement of 11 500 km,

Read more

Read more about circular economy and modernization of elevators through the links below.

Circular economy for elevators

Circular economy is an expression for economical models in a company, society or an organisation, which highlights business opportunities where circular ecosystems are used, rather than linear processes – that have dominated the business climate thus far.

Modernization

Modernization, or renovation of an elevator, means that the elevator is upgraded through the replacement of parts like drive unit, electronics and other wear and tear parts.