This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

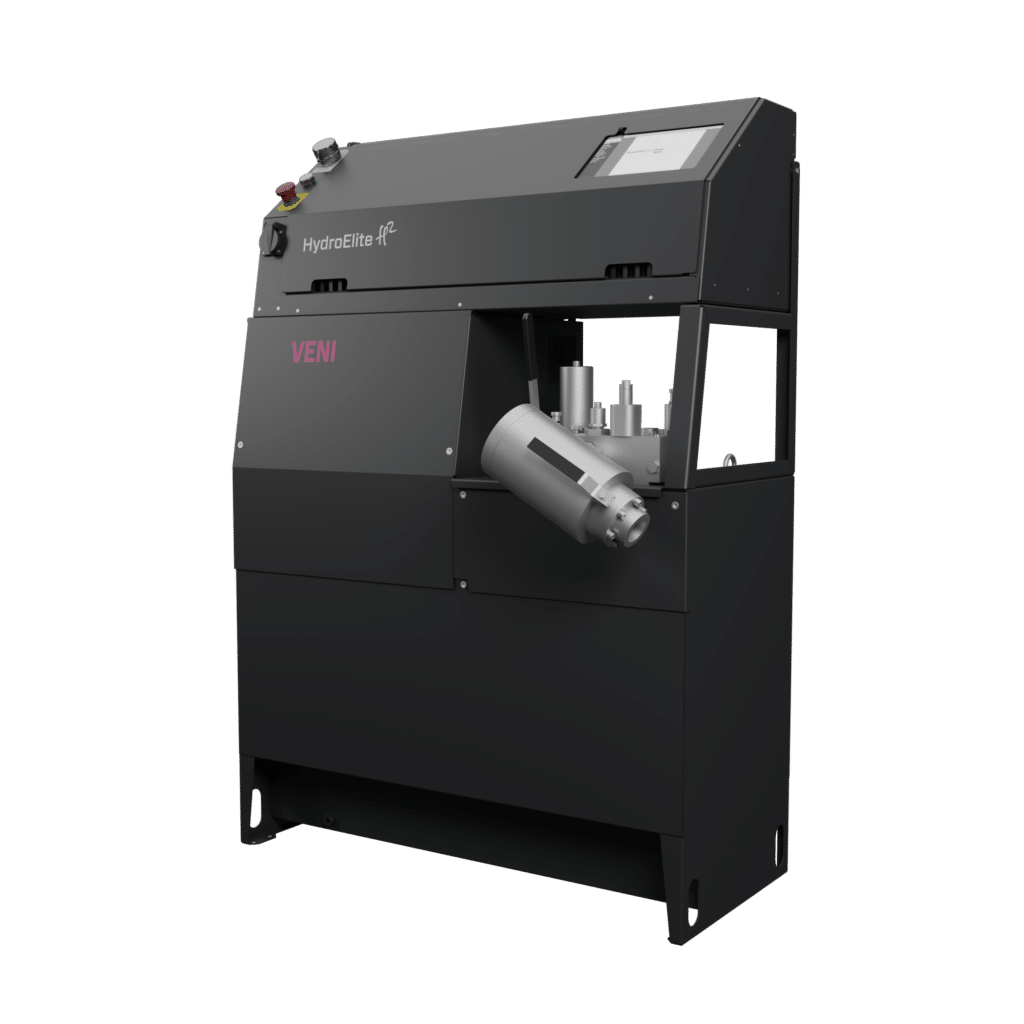

HydroElite VENI

Unique technology with unique servo valve

HydroElite VENI is an integrated drive and control system for hydraulic elevators. It is equipped with Hydroware’s unique valve system which makes it possible for the elevator to go with direct to floor travel, completely without creeping. The valve also does not need to bypass the oil at full speed upwards. It reduces travel time and energy consumption.

HydroElite VENI is available in both H2 and V5 models. H2 is the latest and most innovative lift control system, and it is designed for both the HydroElite H2 and TractionElite H2. With H2, you get one supplier for all your projects, simple installation and a future proof product thanks to our IoT capabilities.

Benefits with H2

When opting for the H2 you get one supplier and one lift controller for all your projects.

H2 is ONE FOR ALL since it is designed for both our TractionElite H2 and our HydroElite H2.

One shaft installation

One user interface

One experience

One partner

H2 – at a Glance

Simple installation

- CANopen Lift technology

- No floor zone sensors needed

- No limit switches needed

- Automated test procedures

- Innovative pit box

- Simple commissioning

- SIL3 certified Position Supervisor Unit

10 ” touch display

- Easy to navigate

- Language options

- Instruction movies in display

- Training sessions simplified

- Integrated diagnostic tool

- Real time and historical data

- Safety circuit overview

- Full accountability

Stay connected – HydroCloud

- HydroCloud connection

- Always updated documentation

- Remote software updates

- Remote monitoring

- Access from anywhere

- Live internal drawings

- Better planning of maintenance

- Constantly evolving IoT

- Local Wi-Fi enables access from smart devices

Benefits with every HydroElite VENI (H2 and V5)

Low energy consumption

HydroElite VENI takes full advantage of the unique valve. The system provides an energy consumption that is up to 50% lower than traditional electronic valves. HydroElite VENI is equipped with a soft starter and a submerged oil motor.

Quick installation

HydroElite VENI is pre-assembled and function tested in our factory, which shortens the installation time. Commissioning is easily done with the help of a learning journey for the hydraulics and one for the floor plan setting. No manual adjustments are required and the valve accuracy increases for each trip.

Increased capacity and comfort

Direct approach to the floor and the fact that no bypass of the oil is needed, gives shorter travel time and increased travel capacity. In addition, the reaction time from a command to start is very short due to the fact that the entire system is perfectly tuned, which also helps to increase the elevator’s capacity and comfort.

No overheated oil

Thanks to the valve’s unique properties, more trips can be made without the oil getting too hot. With a HydroElite VENI, you can often eliminate the risk of overheated oil and the use of energy-intensive oil coolers.

Everything from one supplier

The fact that the drive and control system come from the same supplier provides increased security and easier handling in terms of support, service and guarantees throughout the lifespan of the elevator.

Document

Here is more information about our products and services.

Technical overview of HydroElite VENI (H2 and V5)

Unique Technology

- EN81-20 / 50 certified: common type certificate A3 / UCM

- Soft starter

- Submerged oil motor

- Unique servo valve

- Direct approach to floor

- No by-pass of the oil at full speed upwards

- Self-learning completely without manual settings

- Precise floor adjustment through a self-adjusting positioning system

Energy and capacity

- Up to 50% energy savings

- 10-50% shorter travel time by eliminating creeping and oil bypass

- 20-40% reduced power consumption

- Faster start and temperature and load independence

- Higher traffic capacity without the need for oil cooling

Open and modular

- Flexible and modular to suit all types of installations

- Direct control, pickup, down or full collective and selectors for several elevators in groups.

- Built-in diagnostic system for efficient maintenance and easy troubleshooting

- Remote fault reporting and service diagnostics – option

Verschillende modellen van Hydrowares aandrijvings- en besturingssystemen

TractionElite is verkrijgbaar in MR- en MRL-configuraties.

HydroElite is beschikbaar als H2 en V5 – VENI, VIDI, MINI en MRL.